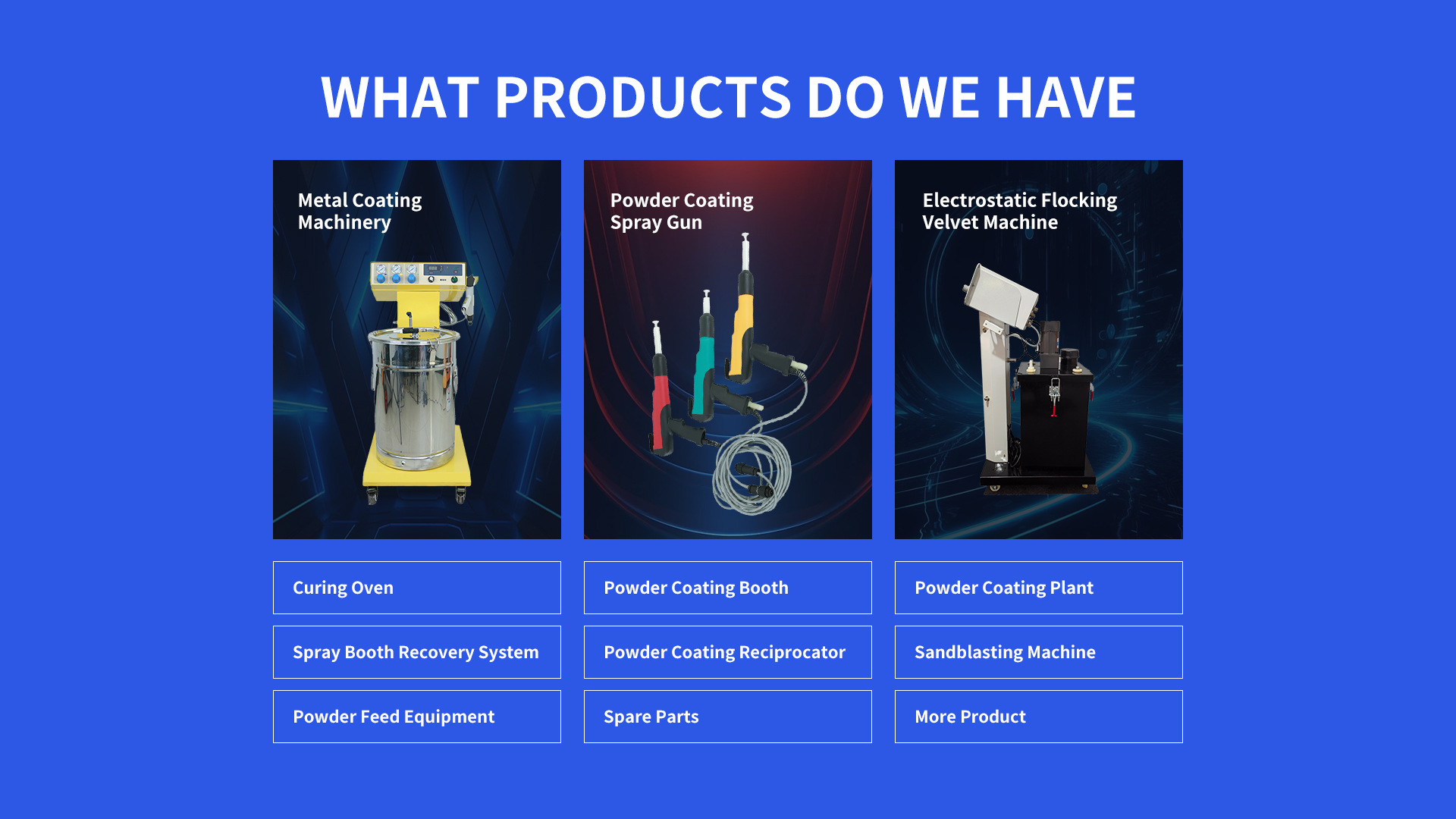

1. Industrial Powder Coating Equipment Overview and Structure

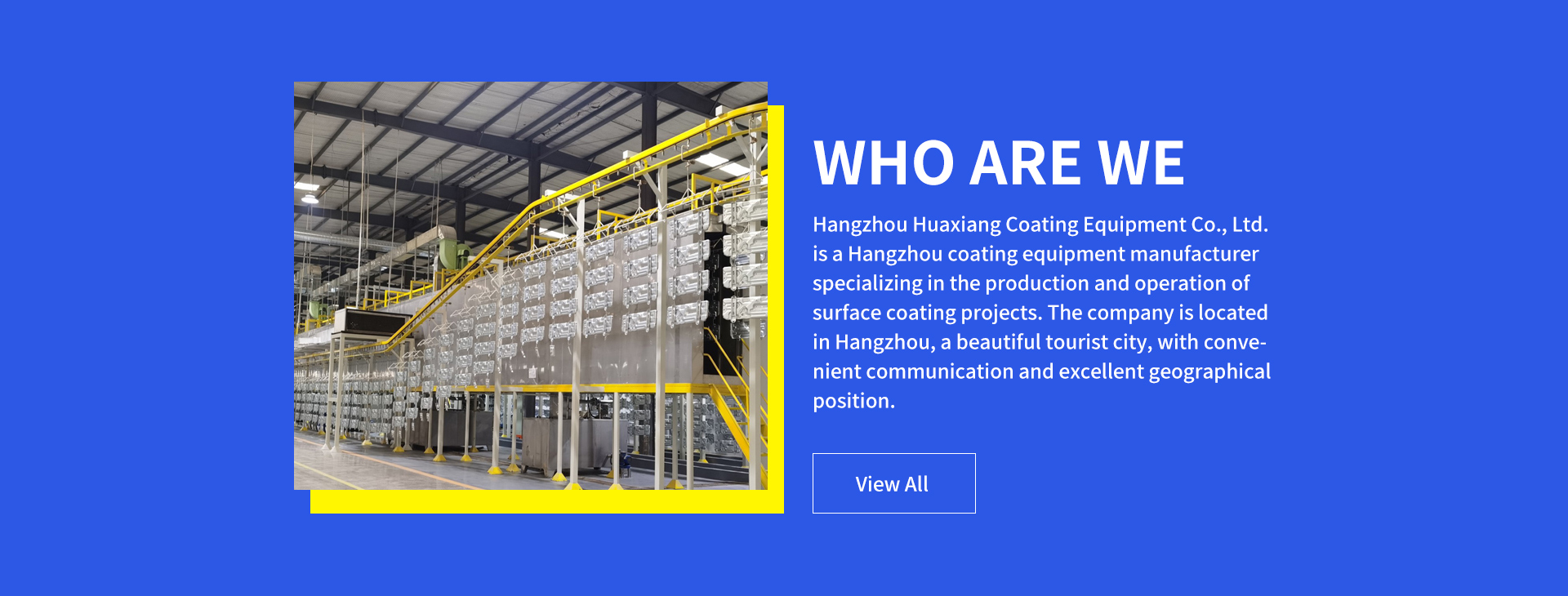

Industrial Powder Coating Equipment encompasses systems designed to apply durable, eco-friendly powder coatings to metal and non-metal surfaces. Key components include a pre-treatment unit (cleaning and phosphating), powder spray booth, electrostatic spray guns, curing oven, and conveyor system. Advanced setups integrate automated controls, powder recovery systems, and real-time monitoring tools. These systems ensure uniform coating adhesion, minimal waste, and high efficiency, making them indispensable in modern manufacturing.

2. Applications of Industrial Powder Coating Equipment

This equipment is vital in automotive, aerospace, construction, and appliance industries. It coats car parts, aircraft components, building materials, and household appliances. Suitable for metals (steel, aluminum) and heat-resistant plastics, it delivers corrosion-resistant, UV-stable finishes ideal for indoor and outdoor use.

3. Pricing of Industrial Powder Coating Equipment

Costs range from 20,000forcompactmanualsystemsto1 million+ for fully automated lines. Entry-level systems suit small workshops, while high-capacity models with robotics and IoT integration cater to large factories. Energy efficiency, customization, and brand reputation significantly impact pricing.

4. Proper Usage of Industrial Powder Coating Equipment

Pre-treatment: Clean and degrease surfaces to ensure adhesion.

Application: Use electrostatic guns to spray charged powder evenly.

Curing: Bake coated items at 300–450°F to form a hardened layer.

Recovery: Recycle excess powder via filters to reduce waste.

Regular calibration of guns and oven temperature checks maintain quality.

5. How to Choose Industrial Powder Coating Equipment

Production Volume: Match equipment throughput (e.g., 100 vs. 1,000 parts/hour).

Material Compatibility: Ensure compatibility with substrates and powder types.

Automation Level: Opt for robotic arms for complex geometries.

Budget: Prioritize ROI by balancing upfront costs and long-term savings.

Leading brands like GEMA and Wagner offer scalable solutions.

6. Safety Precautions for Industrial Powder Coating Equipment

Use explosion-proof equipment in powder-rich environments.

Wear PPE (respirators, anti-static clothing) to avoid inhalation risks.

Maintain proper grounding to prevent electrostatic discharge.

Store powders in dry, ventilated areas to prevent clumping.

7. Design Rationale of Industrial Powder Coating Equipment

Modern designs focus on energy efficiency, modularity, and user safety. Insulated ovens reduce heat loss, while IoT-enabled systems optimize powder usage. Ergonomic layouts minimize operator fatigue, and corrosion-resistant materials extend equipment lifespan.

8. Q&A on Industrial Powder Coating Equipment

Q1: What maintenance ensures long-term performance?

A: Clean spray guns daily, replace filters, and inspect oven heating elements monthly.

Q2: Can this equipment handle multi-layer coatings?

A: Yes, with precise temperature control and compatible powders.

Q3: How does powder recovery reduce operational costs?

A: Recycling up to 95% of excess powder cuts material waste by 30–50%.

Q4: Are these systems eco-friendly?

A: Yes, they emit zero VOCs and comply with global environmental standards.

Q5: What training is required for operators?

A: Basic electrostatic safety, equipment handling, and troubleshooting skills.

This guide provides actionable insights into Industrial Powder Coating Equipment, empowering businesses to enhance coating quality, safety, and efficiency in diverse industrial applications.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com