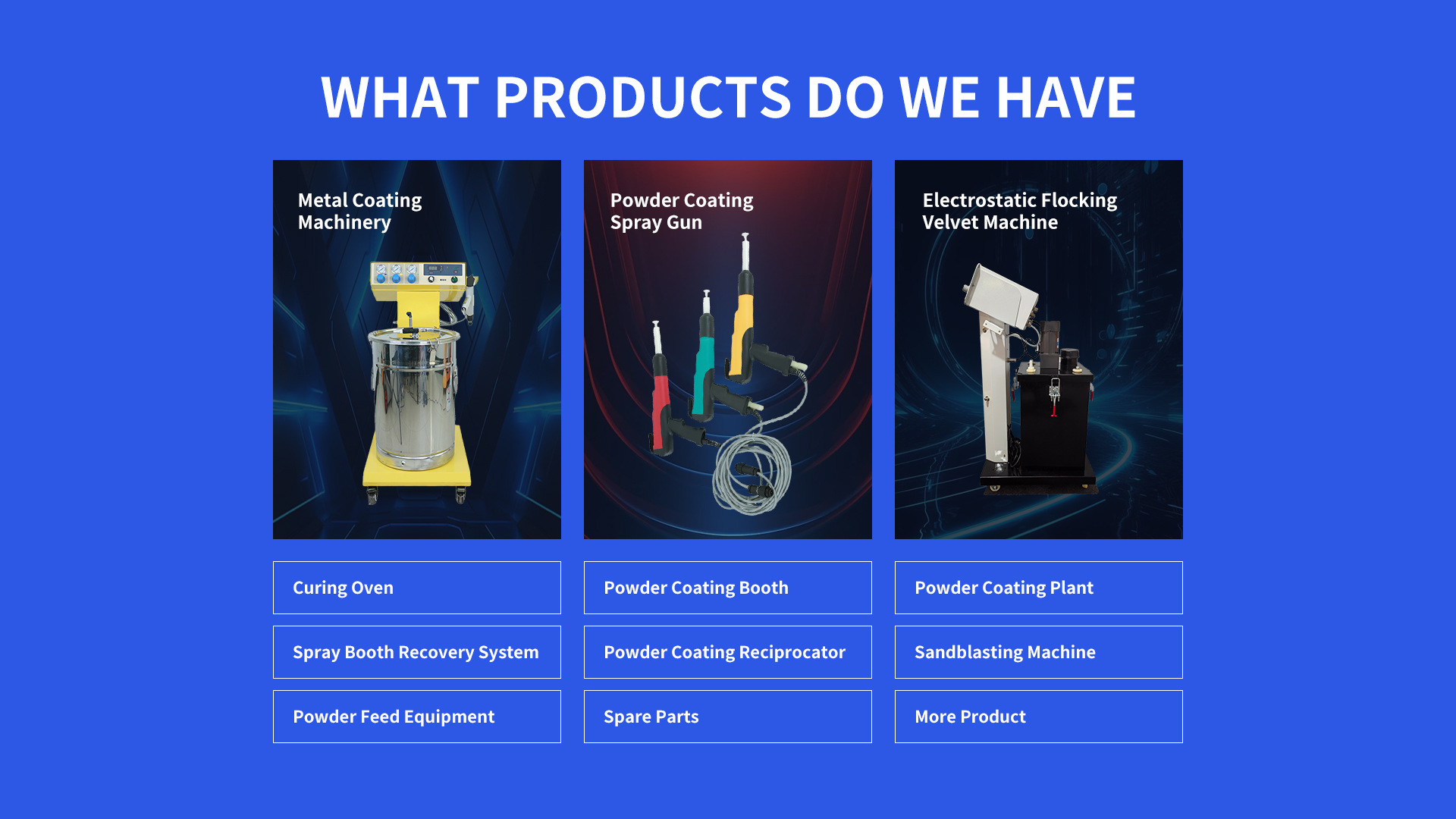

1. Powder Coat Spray Gun Overview and Components

A Powder Coat Spray Gun is a precision tool used to apply dry powder coatings to metal surfaces. It uses electrostatic charging to ensure even adhesion of powder particles. Key components include the spray nozzle, powder reservoir, high-voltage generator, and grounding system. This design minimizes waste and delivers durable, high-quality finishes.

2. Applications of Powder Coat Spray Guns

Powder Coat Spray Guns are essential in industries like automotive, aerospace, and furniture manufacturing. They are ideal for coating car parts, machinery, bicycles, and household appliances. Their eco-friendly nature, with zero VOC emissions, makes them a sustainable choice for modern manufacturing.

3. Powder Coat Spray Gun Price Range

Prices vary from 100forbasicmanualmodelsto5,000+ for advanced automated systems. Factors influencing cost include automation level, powder capacity, and brand reputation. Entry-level guns suit DIY projects, while industrial-grade units are designed for high-volume production.

4. How to Use a Powder Coat Spray Gun Correctly

Clean and ground the workpiece thoroughly.

Adjust voltage (30-90 kV) based on material type and thickness.

Maintain a 6-10 inch spraying distance and overlap passes by 30-50%.

Clean the nozzle and filters after each use to prevent clogs and ensure consistent performance.

5. Tips for Choosing the Right Powder Coat Spray Gun

Production Needs: Manual guns for small-scale tasks; automated systems for large-scale operations.

Powder Compatibility: Ensure compatibility with epoxy, polyester, or hybrid powders.

Energy Efficiency: Opt for models with adjustable airflow and voltage to reduce energy consumption.

Brand Reliability: Choose suppliers offering warranties and technical support.

6. Safety Precautions for Powder Coat Spray Guns

Wear PPE (respirators, gloves, safety goggles) to avoid inhaling powder.

Operate in well-ventilated areas to prevent dust buildup.

Regularly inspect electrical components and grounding to prevent shocks.

Avoid humid environments to maintain electrostatic efficiency.

7. Design Advantages of Powder Coat Spray Guns

Modern powder coat spray guns feature ergonomic designs for user comfort and lightweight handling. Closed-loop systems recover up to 95% of excess powder, reducing material costs. Adjustable settings allow customization for complex shapes, ensuring uniform coverage across diverse applications.

8. FAQs on Powder Coat Spray Guns

Q1: What industries use powder coat spray guns most?

A1: Automotive and metal fabrication industries rely on these guns for high-quality finishes.

Q2: How to troubleshoot uneven coating?

A2: Check grounding, adjust voltage, and ensure consistent spraying distance.

Q3: Can powder coat spray guns work on wood or plastic?

A3: No, electrostatic adhesion requires conductive surfaces like metal.

Q4: What maintenance extends gun lifespan?

A4: Clean filters weekly, inspect hoses monthly, and store in dry conditions.

Q5: Are powder-coated items heat-resistant?

A5: Yes, cured coatings withstand high temperatures, making them ideal for engine parts.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com